Alkylated Naphthalene for Food Grade

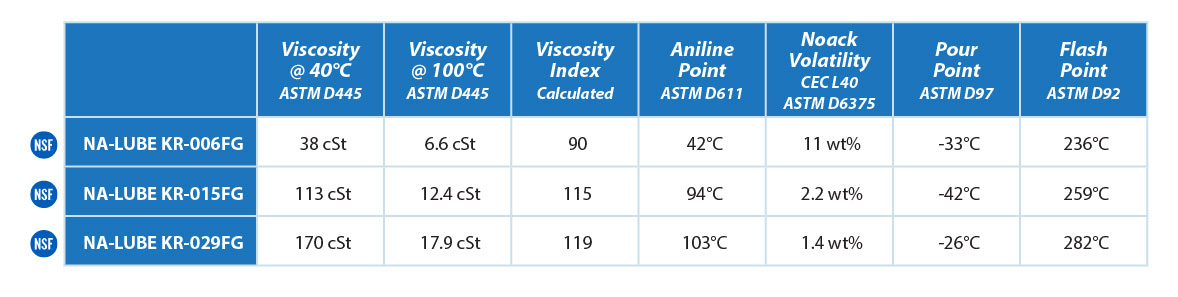

The NA-LUBE KR line includes three grades that are FDA 21 CFR compliant for incidental food contact and registered with the NSF as HX-1 lubricant additives.

Bakery Oven Model Formulation

Bakery Oven Model Formulation (ISO VG 220)

H1 Formulation based on PAO with a total additive top treat of 2.5% wt. containing:

–NA-LUBE® AW-6509 (Triphenyl phosphorothionate)

–NA-LUBE® AO-142 (Alkylated diphenylamine)

–NA-LUBE® ADTC (Ashless dithiocarbamate)

–BHT (Butylated hydroxytoluene)

–NA-SUL® CA-770FG (Calcium sulfonate)

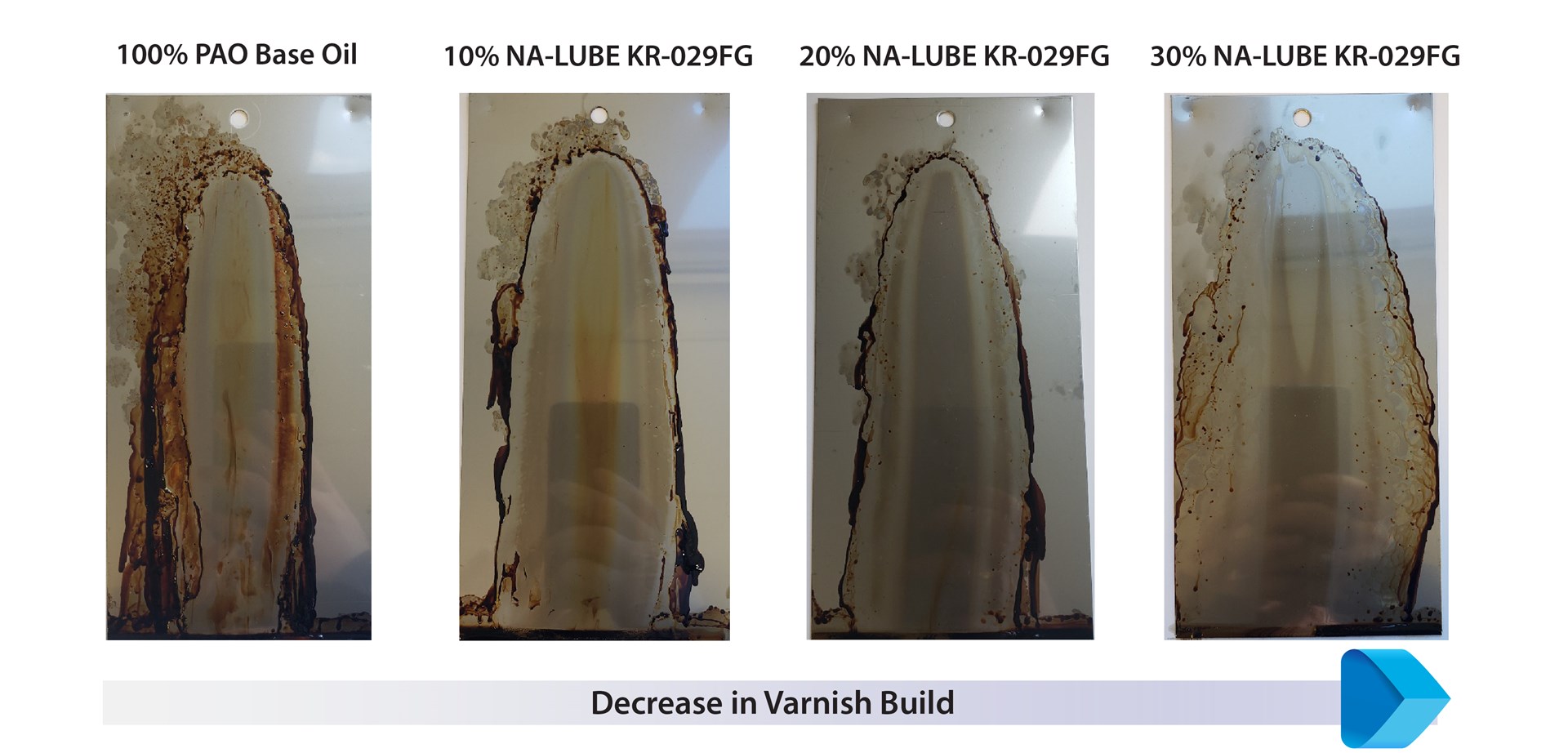

Panel Coker

As the fluid flows down the surface of the panel, a wetting pattern emerges based on the characteristics of the fluid. Wetting is an important feature to a fluid’s ability to create a tribological film. A fluid with good wetting has been observed to create a wide inverted parabola. High performance fluids with excellent thermo-oxidative stability and good wetting will typically result in an open pattern with faint or low deposits outlining the inverted parabola. At high temperatures, a lack of thermo-oxidative stability or wetting will cause the pattern to close at the bottom of the panel leading to coke build-up.

The pictures show the coking pattern of the fluid displayed an increased opening at the bottom of the panel in addition to a lower 3-dimensional build of the solids along the periphery of the wetted flow route. The lower build of coke suggested both improved thermo-oxidative stability and solubilization of pre-formed and/or formed deposits.